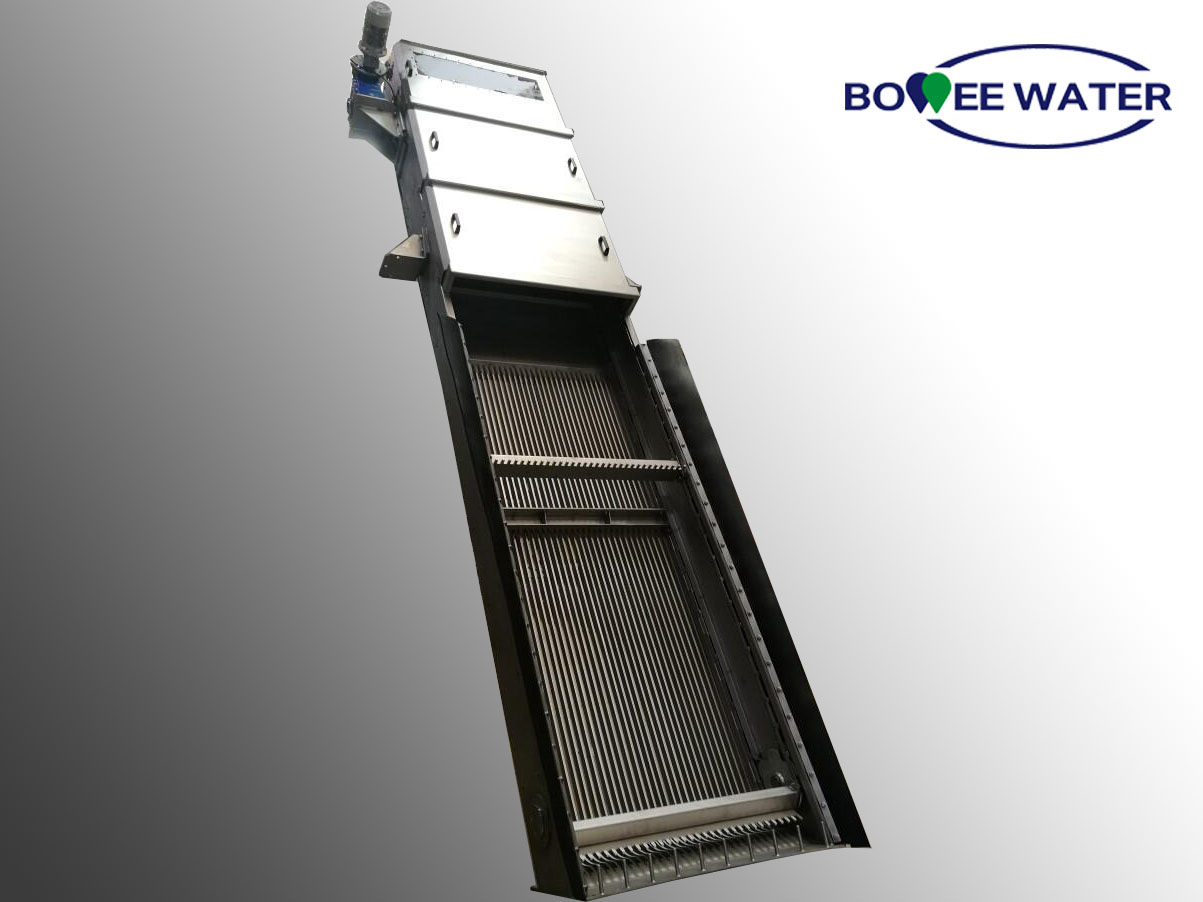

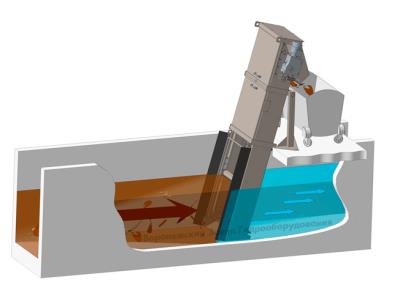

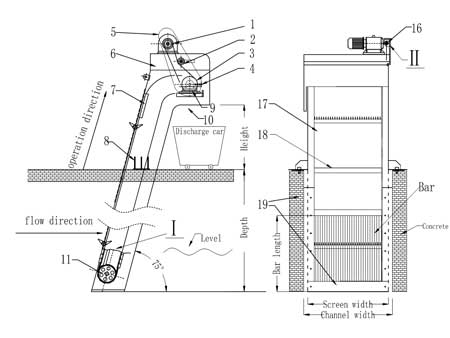

Mechanical Bar Screen also called as rainwater screen, is widely used to block and get rid of floating debris in rainwater pump station, wastewater pump station, water supply pump station and influent pump station of sewage treatment plant municipal wastewater treatment.

Specifications:

Dimension: Customized

Material: SS304, SS316 or Customized

Rake Material: SS304,ABS or Customzied

Rake spacing: 20-100mm

Inclined angle: 75°

Motor brand: First-class motor, Nord or SEW is optional